Surface control and measurement system for dental implants

Fully automated machine vision system for precision measurement and surface analysis of dental implant components.

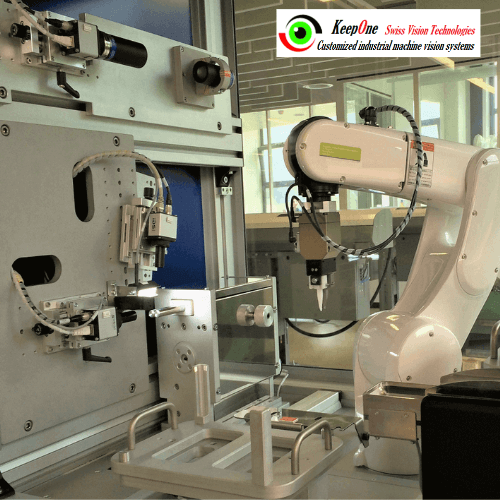

KeepOne Swiss Vision Technologies has developed a fully automated robotic system for surface measurement and inspection dedicated to the DENTAL IMPLANTS market.

Vision systems for dental implants Manufacturing integrity and part conformity are closely linked to patients, their safety and, ultimately, their lives.

Regardless of whether the manufactured part is a dental implant, a bone screw or any other component, accurate and thorough quality inspections are a fundamental requirement.

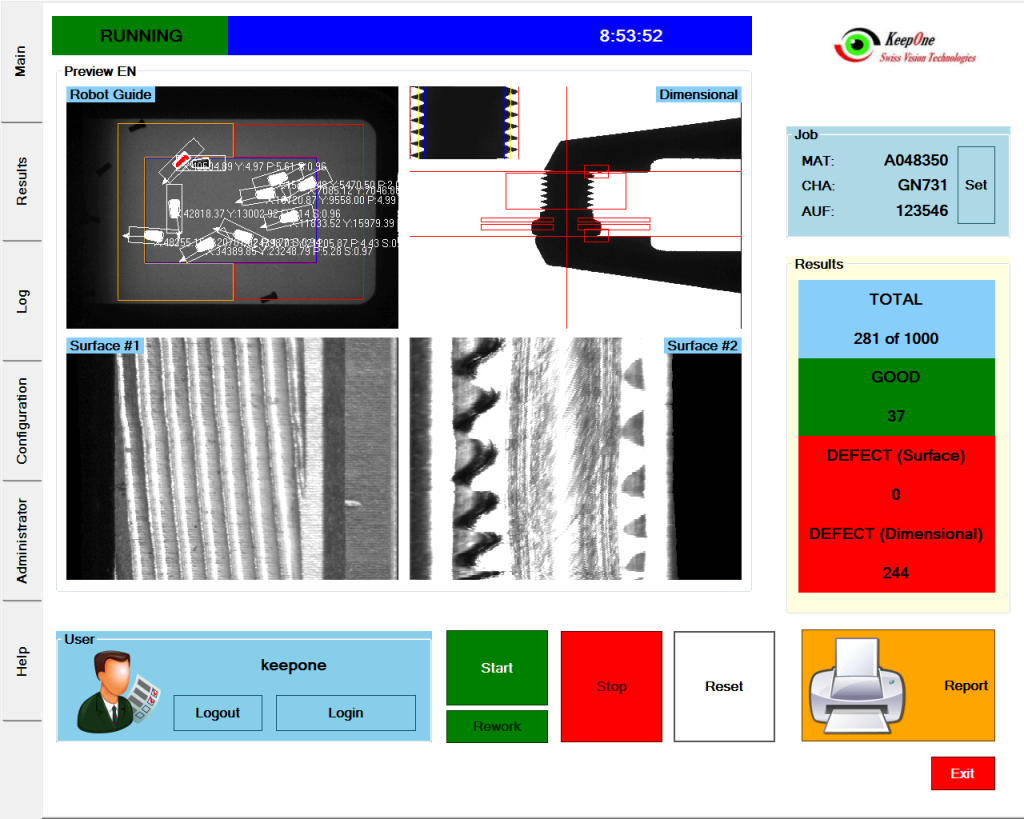

KeepOne Vision systems for dental implants perform surface inspection and rapid measurement of the external dimensional profiles of various parts, such as screws, implant screws and threaded inserts.

Rapid processing requires a scan of the part profile, allowing many dimensions to be measured in the same fast cycle time.

KeepOne Vision systems for dental implants are designed for use in production floor, for immediate control of part dimensions in the manufacturing process.

After recognition of the article, which is located on the vibrating base, the robot picks up the part and deposits it on the surface inspection station.

In the same cycle, the part is picked up and ready for dimensional inspection.

After a 360° rotation to check the integrity of the head and thread, the part is picked up and analyzed in the measuring station.

The entire cycle time for analyzing the workpiece is approx. 4 seconds.