HypériOne learning technology. Extremely fast AI based recognition and classification algorithms

Our systems help solidify your medical quality control processes, we offer a range of solutions that meet your specific needs and those of the wider pharmaceutical sector.

In pharmaceutical manufacturing applications, quality is always the top concern. Stringent FDA standards mean high levels of liability for errors in production. Machine vision system for pharmaceutical plays a major role in delivering consistently high-quality products in the pharmaceutical industry, but machine vision can also deliver productivity gains, within the confines of strict quality demands.

Machine vision technology for pharmaceutical has advanced considerably since its initial emergence into the industrial sector. It’s now suited for very specific applications in the pharmaceutical industry and creates productivity in a number of ways.

- Code validation – Package integrity

- Fill level – Surface defect

- Cap integrity – Labeling

- Contamination Safety

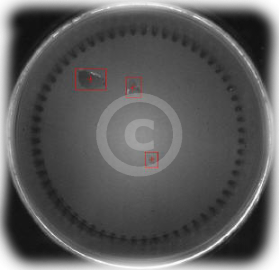

GLASS-SLIVER-INSPECTOR is a analysis and inspection System especially conceived for thè detection of foreign bodies within bottles in colored glass and containing thick and dark liquids.

The System helps to enhance security in terms of possible glass fragments created by ruptures or cracks after filling and capping phases especially with screw caps.

GLASS-SLIVER-INSPECTOR is optimized for the pharmaceutical sector while detecting glass cracks in thick and colored liquids, but it may be unlimitedly used also for control in fillers and cappers for bottles of wine, beer and dark-colored drinks.

Inspection machine or the System may be used both out of line in a totally autonomous manner and in line with filler and capper.

GLASS-SLIVER-INSPECTOR is equipped with three high-resolution TV cameras, a special illumination System and a rotation System for a 360- degree analysis of thè bottle.

Thanks to its powerful processing technology it may carry out full inspections onto bottles in about 100 ms and identify fragments of 1 mm3.

Within the pharmaceutical sector GLASS-SLIVER-INSPECTOR may be provided – upon request – with technical documentation in compliance with FDA directives and GAMP norms.

Machine Vision System for pharmaceutical is simple to set up and scales with your business. Learn how automated quality inspections can work for you.

packaging integrity

Ensure that safety seals and caps are present and properly placed. Check that blister packs are fully intact with no damaged or missing capsules

label accuracy

Verify that labels are accurate and contain all information required for compliance. Ensure print quality of text and barcodes and confirm the attachment of additional instruction leaflets.

product quality

Confirm that products are consistent in appearance and size before packaging. Detect the presence of particulates and broken tablets.

traceability

Traceability: Read and verify the accuracy of 1D and 2D barcodes, text, and numbers printed on labels, cartons, films, and other surfaces. Automatically and securely log data to create an audit trail in the HypériOne dashboard.