Improving productivity will be an essential aspect in the future.

The automotive optical sorting machine industry is focused on the safety and traceability compliance through inspection, integrity, marking and robotics system solutions. In addition to quality and dimensional checks, vision systems can be used in robot guidance and product identification for a ‘pick and place’ operation.

The next generation GigE Vision cameras and Smart Cameras have smaller profiles, faster processing speeds, higher resolutions, and an array of advanced functionality. Whether guiding robots on a production line, verifying markings on parts and labels, performing test and measurement functions or alignment applications, today’s Vision Guided Robotic applications continue to drive the development of vision technologies to meet changes in production requirements, and demanding business objectives.

Continuing innovations in machine vision technology is taking automation beyond the traditional industrial production floor, into a host of new markets and opportunities for inspection and measurement applications. Higher resolution sensors, faster processing speeds, along with increased capabilities of various vision tools, have enabled automated processes to detect a flaw in a single pixel of our 4K LCD TVs. We can now enhance the quality of mass produced products by inspecting almost every component down to a fraction of an inch, or teach a robot, through Vision Guided Robotics (VGR), with exacting precision on where to pick up an item, and where to put it down. We can increase the speed in which we assemble printed circuit boards by using vision systems that can pick and place tiny microelectronic packages into an exacting footprint.

All of these incredible advancements in the vision industry have resulted in automotive optical sorting machine, having a lower cost of acquisition, greater performance, and vast quality improvements. This has made it easier for companies to automate processes to meet the competitive demands for increased production rates, higher quality, lower costs, and faster time to market.

- 100% automatic inspection Inline capable

- Single target calibration procedure

- Gauging accuracy of 0.01mm

- Database archiving for analysis

All of this is being accomplished as a result of today’s vision technology, and ever evolving imaging standards. These innovations are allowing us to take full advantage of today’s computers, with their increased processing power, and state of the art communication channels. Vision standards such as Camera Link, Camera Link HS, and newly developed CoaXPress, and USB 3.0 Vision are allowing us to create next generation vision systems.

For more information discover all our products.

robotic vision

Growth of the robotics industry in the 21st century has been unparalleled. Technology has taken us from the image of large material handling robots picking up cars and moving them around, to the first in home robotic vacuum cleaner. It is important that we distinguish between these two types of robots. They are both very much a part of the automation age we now live in, but have very different vision requirements. The first type, used in manufacturing and warehousing of products, are referred to as Industrial Robots. The type that assist us in our day to day living, are referred to as Service Robots.

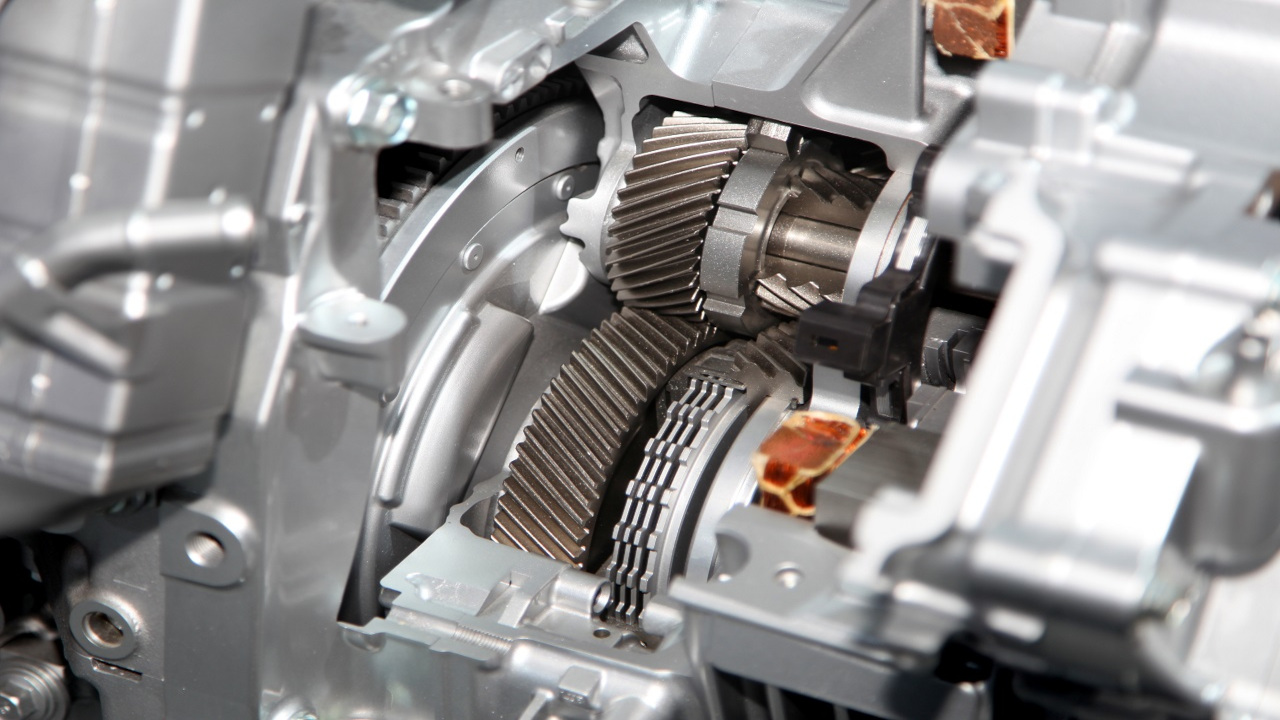

2D and 3D precision measuring system

Utilizing a combination of software, optical, and ultra-high resolution image formation technology, The K1_MS23D is the single solution for precision 2D and 3D measuring. Materials can be measured from a wide variety of industries including Aerospace, Automotive, Plastics, and Electronics. The K1_MS23D is designed with exceptional optical capabilities in a single system for efficiency, accuracy, and cost-effectiveness.

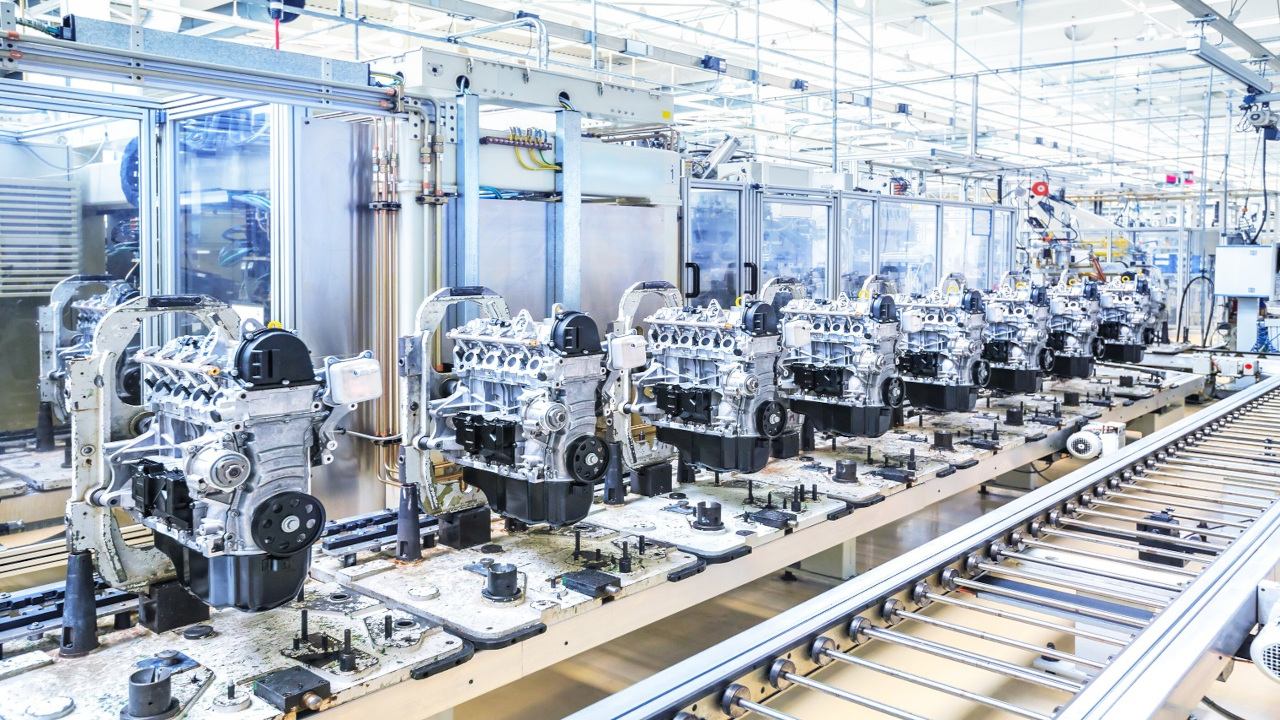

Manufacturing & assembling automation

Innovations in Vision Guided Robotic systems (VGR) are affording automotive manufacturers and suppliers greater flexibility and increased capabilities to face the complex changes in the shifting and competitive industry landscape. Manufacturers and suppliers are looking for vision solutions that allow them to respond effectively to changes in consumer demands, shorter technology cycles, new products and options, and the need to innovate to maintain their competitive edge. Compounding their challenges, they must also continue to demonstrate their ability to increase product quality and throughput, while reducing component costs and time to market.